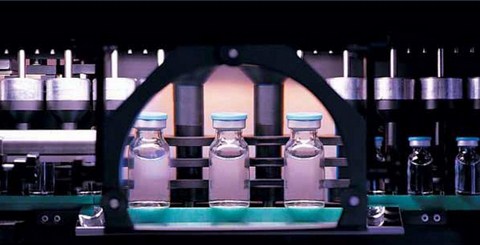

Steriles

Contamination is a killer, and aseptic and sterile handling is essential for the integrity of all pharmaceutical products and devices.

And it is just as complex, as it is vital – both in terms of technology and compliance with regulatory requirements.

Traditionally, sterile and aseptic handling has been done in a conventional cleanroom, but today technologies, e.g. isolators, Restricted Access Barrier Systems (RABS), single-use systems and sterile transfer of materials, can ensure high Sterility Assurance Level (SAL).

At SLB Engineering we have in-depth insight into aseptic and sterile fill and finish processes.

This includes our first-hand experience operating in these environments, extensive knowledge of regulatory developments, practical experience in integrating the different technologies and awareness of the industry’s most recent developments. We can advise you on finding the right technology that best matches your needs. And we can help you balance your investment costs, operational costs, regulatory requirements and risks.